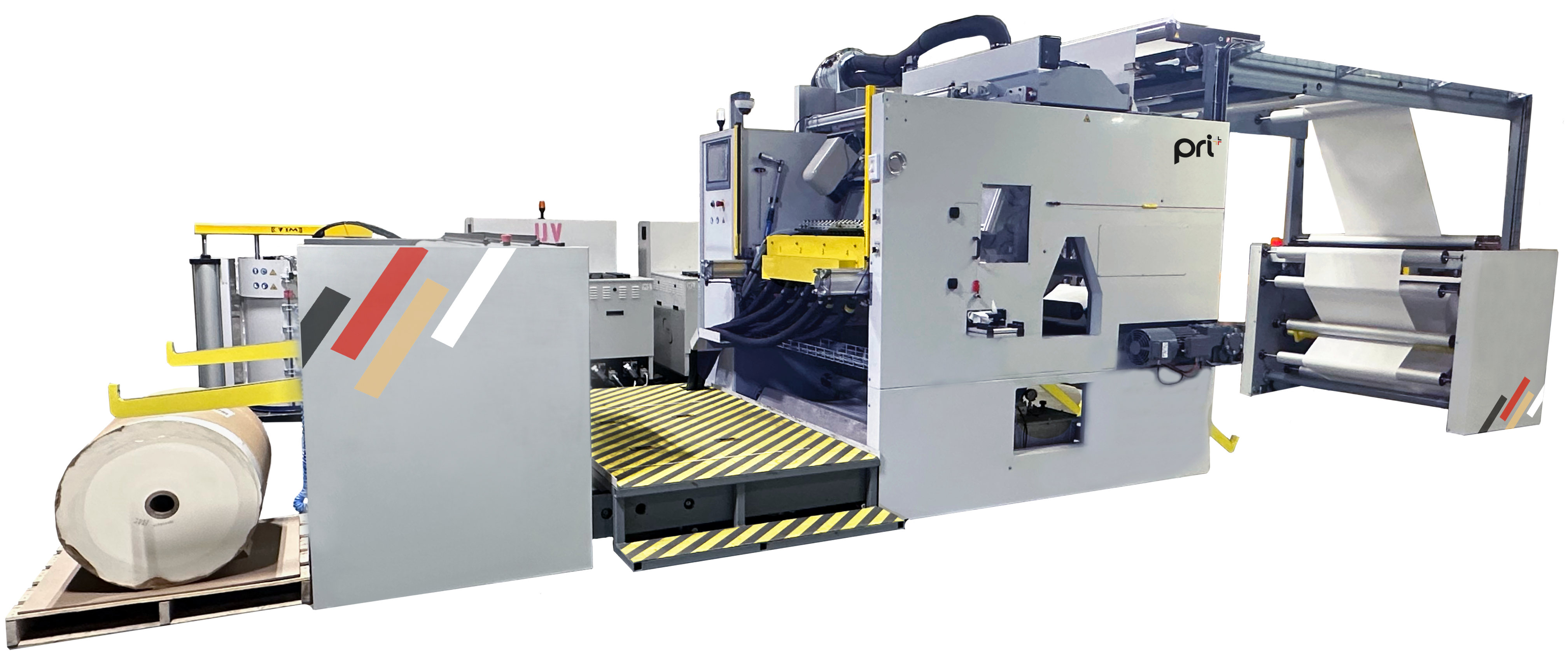

Thorough Inspection with Quality Built In

Real-Time Defect Detection — camera scans the web for any imperfection

Data-Driven Quality — logs every roll for verification & continual improvement

Recipe Storage — saves job settings for repeatable results

Corrective Actions — tracks deviations and initiates immediate response

Automated Tension Control — prevents stretching, misalignment, and other defects

👉 RELATED: Converting Quarterly highlights how integrated inspection systems are transforming web coating processes

Master Coatings on Every Roll

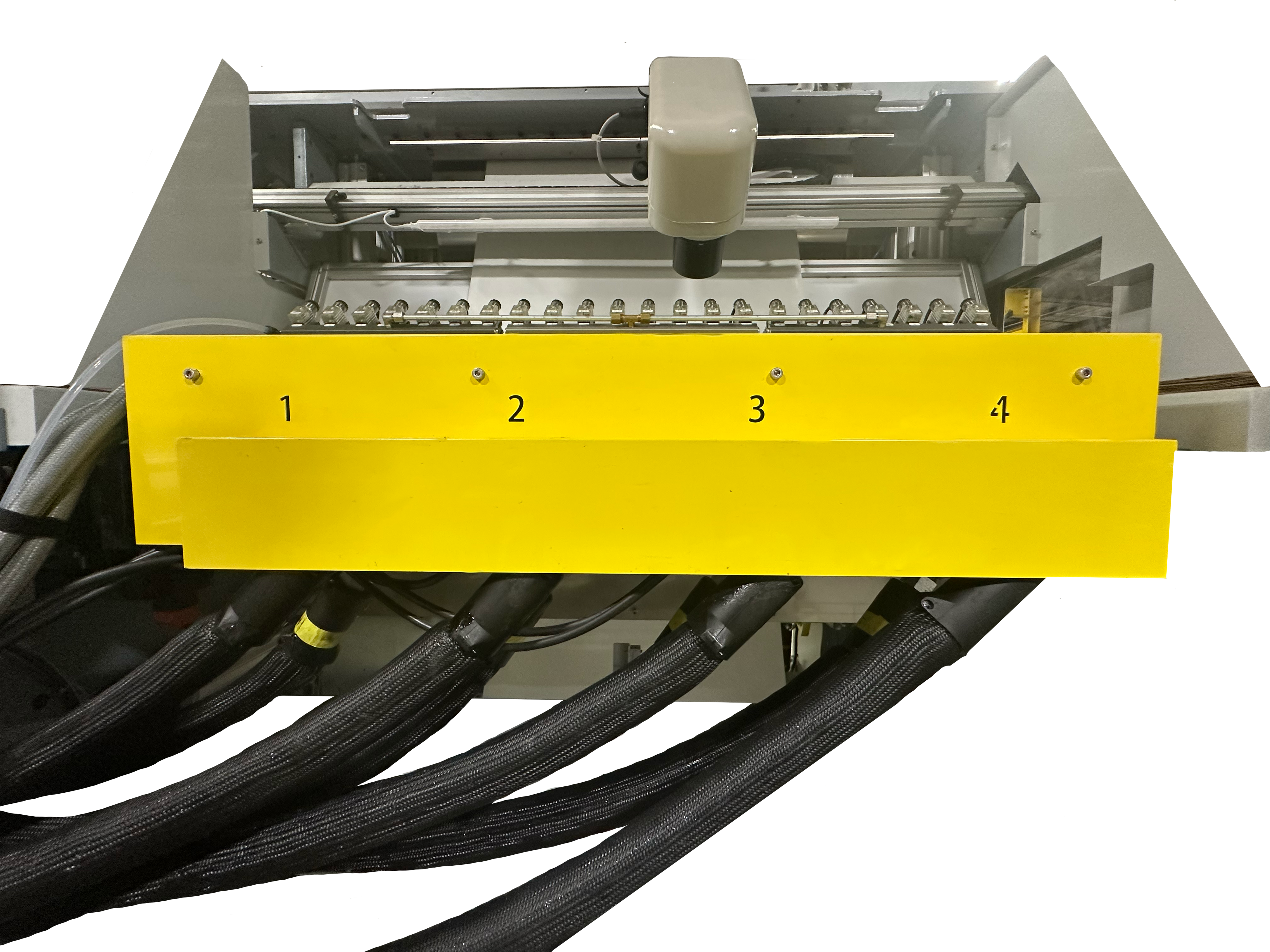

Automatic Adjustments — Dialed in for the most accurate coat weights

Closed-Loop Gluing — Controlled environment prevents impurities

Four Independent Zones — Each with its own pump for uniform distribution

Wide Web Capability — homogeneous & streak-free coating

👉 RELATED: Discover why consistent coating and independent zone control are critical for high-quality label stock

Melters & Drum Unloaders Designed for Efficiency

Separate Systems for UV and Hot Melt — avoids cross-contamination

Consistent Temperature — stable heat for reliable adhesive flow

High-Capacity Handling — works with large runs

…all leading to less downtime & quicker runs — product delivered when you need it

UV Technology for the Next Wave of Durable Labeling

On-Board UVC Lamp — no secondary curing; runs on your finishing equipment

High-Intensity Surface Curing — for clean converting & strong chemical resistance

Eliminate Edge Defects — oversized lamp width ensures cure across the entire web

Integrated UVC Sensors — monitor lamp output to maintain optimal cure levels

Watch Our Talk with L&NW

then, see how the coater got set up