label stock with

unmatched durability

test our high-performance stock

in real world conditions

talk with an expert

about your specific needs

Properties

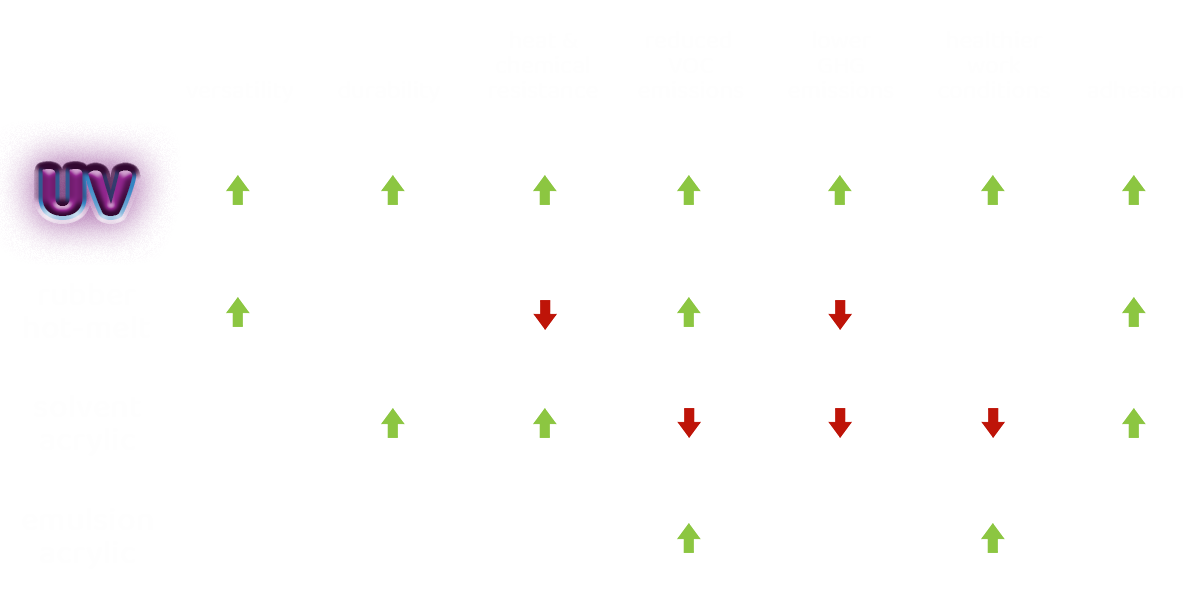

long-lasting durability

Labels should last as long as the products they’re on. UV acrylic adhesives create bonds that won’t break down over time, resisting peeling, lifting, and failure—even in the toughest conditions.

wide application versatility

One adhesive, countless applications. UV acrylics bond seamlessly to a variety of surfaces—smooth or textured, rigid or flexible, indoor or out— making them the go-to choice for demanding industries. From industrial equipment to medical devices, get a label construction that adapts to your needs without compromise.

superior heat resistance

High temperatures shouldn’t mean label failure. UV acrylic adhesives maintain their strength and stability in extreme heat, resisting softening, oozing, or delamination. Whether exposed to industrial ovens or sun-scorched surfaces, these adhesives hold firm when others give way.

higher chemical resistance

Harsh chemicals are no match. UV acrylic adhesives stand up to solvents, cleaners, and industrial chemicals without breaking down, lifting, or weakening. When exposure is unavoidable, rely on a bond that stays strong.

less sunlight degradation

UV exposure breaks down ordinary adhesives—but not this one. UV acrylics resist yellowing, cracking, and breakdown from prolonged sunlight, keeping labels clear, legible, and securely bonded in even the harshest outdoor conditions.

greater adhesive clarity

Crystal-clear adhesion that stays transparent. UV acrylic adhesives deliver superior clarity, ensuring your labels remain sharp, vibrant, and free from haze or clouding—perfect for high-visibility applications and a no-label appearance.

Coating Mastery

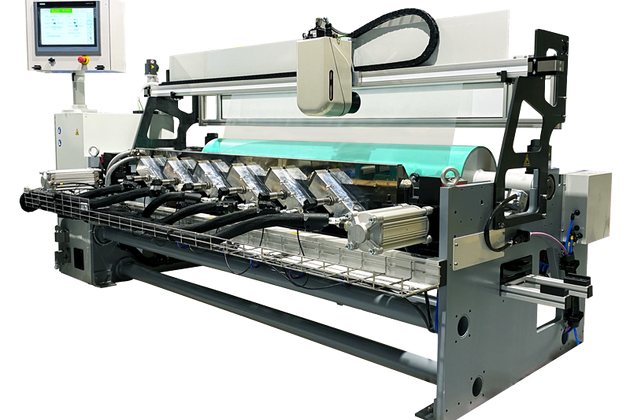

advanced coating system

- homogeneous & streak-free coating (up to 39 in)

- enclosed gluing system

- minimized adhesive pollution

- reduced maintenance downtime

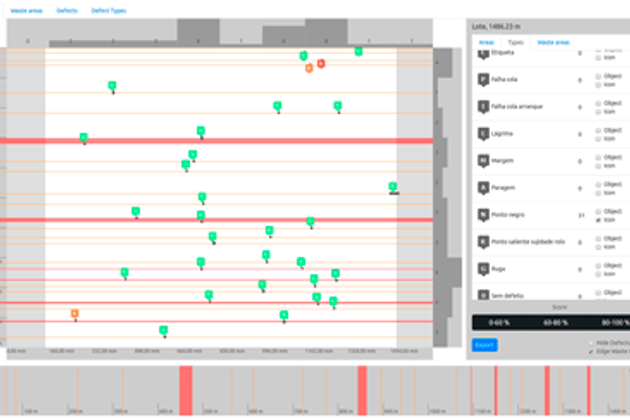

vision inspection system

AI-powered system

to detect, classify, and record coating errors in real-time

- detects all defects during coating to allow for elimination during slitting

- real-time error detection for immediate corrective response

- Stored reports for continual improvement actions

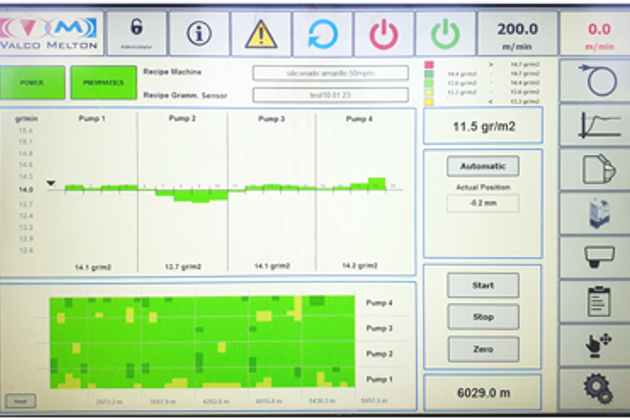

grammage control system

automatically measures, adjusts, and records

adhesive coat weight through 4 zones across the web

- infrared sensor scans across the application

- makes adjustments without stopping the line

- detailed traceability for each production batch

- speed, tension, grammage, die position, pressure, temperature, UV dosing, and more

common applications

mowers

machinery

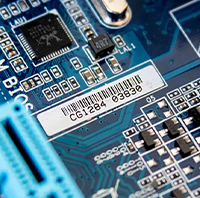

electronics

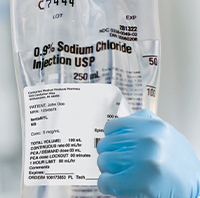

medical supplies

automotive

solar panels

and so much more!

Going Green